There's More to the Cost of Injection Molding Than the Bottom Line

How expensive is injection molding? It's a common question, and it's also deceptively simple. Any injection molder can quote you a price. Since you expect to pay for the service, it's not necessarily a matter of understanding if or even how much you'll invest injection molding.

Rather, knowing when to strategically invest in the process is key in managing the cost of injection molding to achieve exceptional outcomes.

Generally, the more resources devoted to product development on the front end, the greater the cost efficiencies downstream.

strategic design and engineering support

Many factors impact the up-front cost of injection molding projects. To appropriately prioritize and invest in design and engineering processes with the most impact, working with a custom injection molder with proven experience in these areas is essential:

Design for Manufacturability (DfM) Analysis

Intentionally and proactively designing products to optimize all facets of manufacturing is at the heart of Design for Manufacturability (DfM).

The value of DfM analysis lies in the focus placed on finding practical solutions to project impediments that could jeopardize successful outcomes.

In short, DfM analysis defines opportunities for reducing costs, improving manufacturability, and increasing speed to market because it enables engineers to delve into:

- Potential part moldability issues and solutions during the design phase

- Part design modifications to simplify tooling

- Opportunities to make appropriate materials substitutions to enhance part quality and/or reduce costs while meeting cosmetic specifications

- Production efficiencies that improve processes and part quality

- Cost efficiencies that lower per-part prices

Plastic Part Design

Input from a trusted injection molding partner from project conceptualization through production is the best way to optimize the design process. Guiding the product vision and performance goals with deep knowledge of technology, material science, and manufacturability gets the entire team on the same page in terms of expectations. It also results in the best possible product at the lowest possible cost.

Product Testing & Analysis

Determining the best possible injection molding process for a given product doesn't happen by chance. Injection molders house engineering teams specially trained in scientific molding in order to arrive at consistent, repeatable high-quality outcomes throughout all production cycles.

Sophisticated computer modeling is key in testing design features, material characteristics, and mold design. Among the most popular and comprehensive are Moldfill analysis (demonstrates how plastics behave inside of a tool) and Finite Element Analysis (models how products behave across a range of variables, using a virtual environment).

Plastics Selection Support

There are more than 25,000 engineered materials available to manufacture complex applications, and high-performance blends and hybrids can be formulated to meet the very specific requirements of complex plastic parts and products.

The wide variety of available plastics opens up a number of possibilities, but selecting the proper resin takes a thorough understanding of your application. More specifically, it takes guidance from a proven injection molding partner. Kaysun, for example, has an extensive in-house database that allows our plastics engineers to have greater insight into how different plastics will respond to different combinations of process variables so they can align materials and needs.

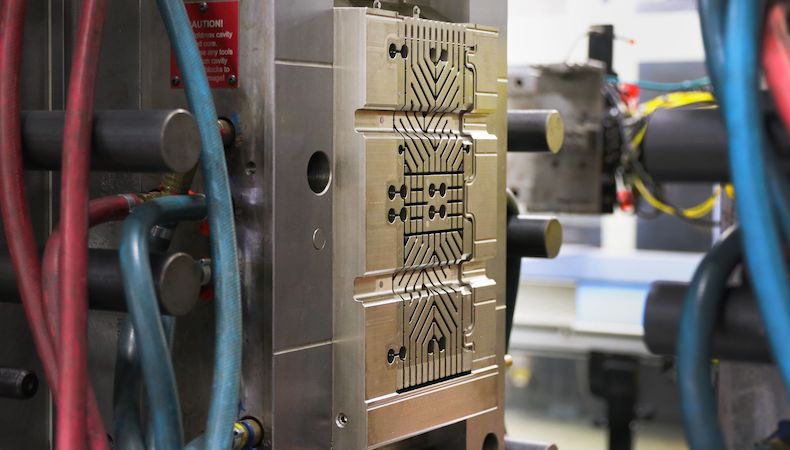

Tool Building

Tooling for custom injection-molded plastic parts is highly technical, and usually dependent upon the scientific molding process. How plastics behave, the steel grade chosen for the tool, and design intricacies such as tight tolerances all play a part in proper tooling, as well as how the tool ultimately performs during exacting pre-production qualification testing.

downstream benefits and cost savings

Depending on the nature of and market for your product, greater effort up front in accounting for project contingencies results in several cost-cutting downstream benefits, including:

-

Improved part consistency and production run replication

- Minimal rework and scrap

-

Increased part reliability and fewer returns

-

Greater production line flexibility and repurposing without requiring excessive maintenance or downtime

-

Faster time to market for a distinct competitive advantage

- Dependable on-time delivery (OTD) that strengthens customer relationships.

All told, attaching a specific dollar amount to the “How expensive is injection molding?” question isn't as easy as it appears. Therefore, it is beneficial to have the Kaysun engineering team assess where to balance your resources between initial investment and longer-term returns.

For more on the benefits of leveraging supplier expertise to manage product quality and bottom lines, read How Injection Molder Partnerships Influence Project Costs. Click the button to access your copy of this valuable guide now.

Subscribe

TO OUR BLOG

How Do Injection Molder Partnerships Influence Project Costs?

You Might Also Like...

How Kaysun’s Culture of Sustainability Benefits OEMs and The Planet

Injection-molded parts and products are staples for OEMs in industries ranging fro…

READ MORE

12 Common Injection Molding Questions — Answered!

Injection molding is a versatile and precise process, making it ideal for OEMs tha…

READ MORE

How Centralized Material Handling Streamlines Injection Molding

We consistently look for new ways to deliver timely service and top-quality parts …

READ MORE