Injection Molding Capabilities

As industries and offerings become more complex, OEMs are compelled to innovate at a faster pace to stay competitive. Custom injection molding plays a pivotal role in getting reliable parts and products to market — provided the molder is able and committed to delivering expert injection molding capabilities in every aspect of the partnership.

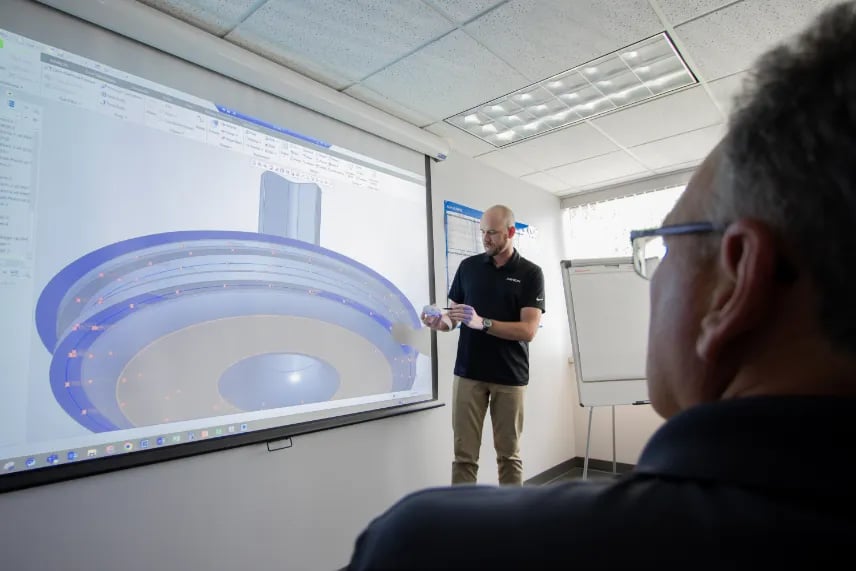

Engineering Support

Kaysun takes a holistic approach to complex injection molding, implementing key methodologies and processes such as DfM Analysis, Material Selection, and Metal-to-Plastic Conversion to inform decision making. Our comprehensive in-house engineering support services provide the foundation for consistency, quality, and success in injection molding projects.

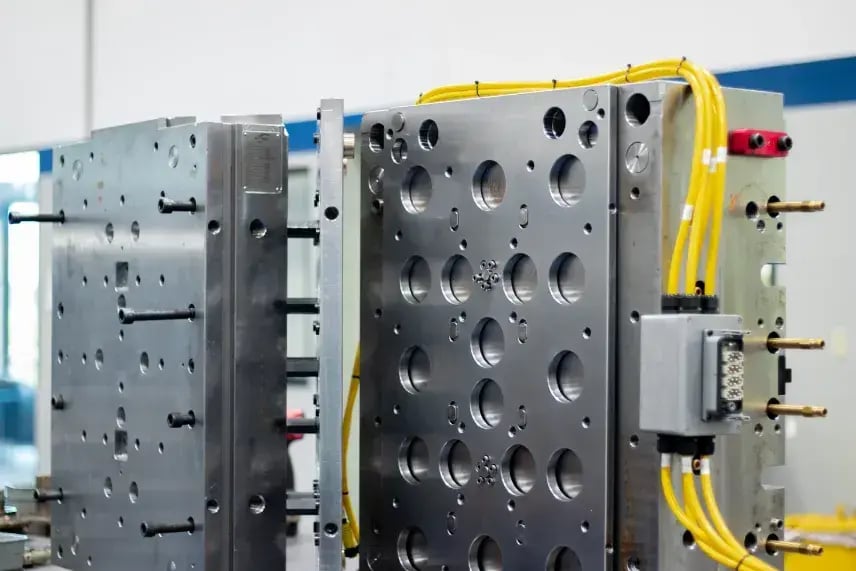

Tool Building

Kaysun’s in-house expertise in tool design, qualification, and management gives OEMs peace of mind that the most important investment in injection-molded part quality is included within the larger production plan and process, right from the start. From choosing materials that prolong tool life to designs that consistently optimize repeatability and production, Kaysun is here to help.

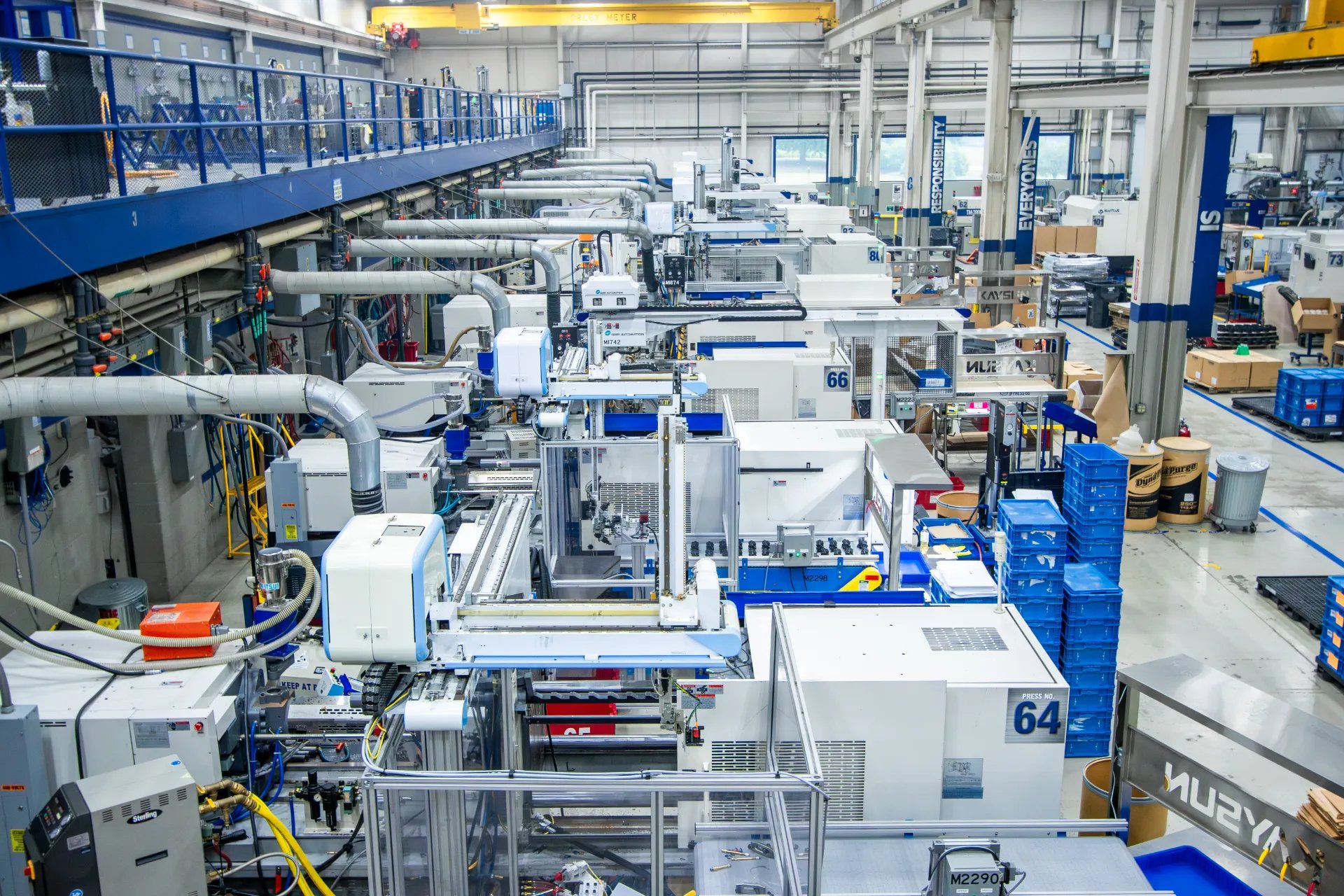

Custom Injection Molding

Custom plastic injection molding is ideal for complex applications requiring detailed specifications, but not every injection molder is positioned to delve into sophisticated processes such as scientific molding and overmolding to meet the exacting standards of OEMs and complex applications. Kaysun believes in the power of partnership, and has the experience, methodologies, and technology to overcome issues and help achieve goals.

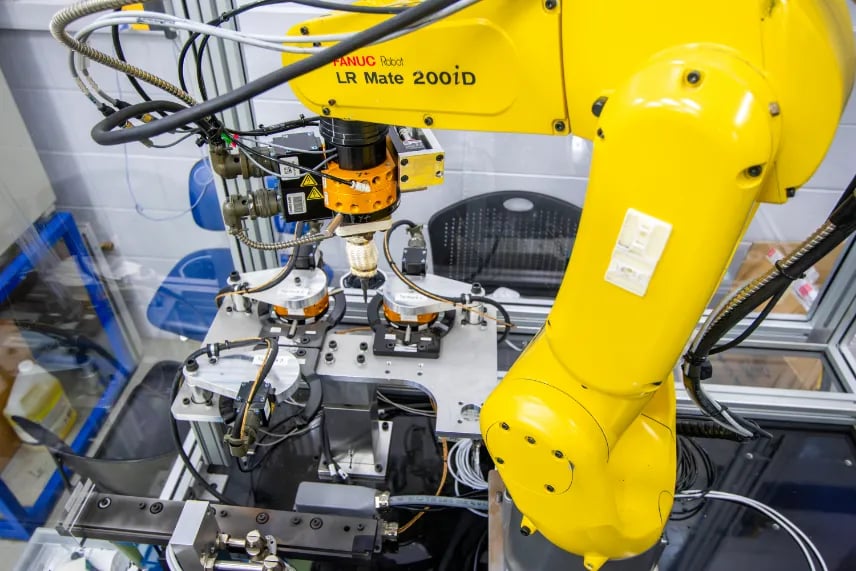

Value-Added Services

Secondary operations required post-mold to finish a part or product are often delegated to vendors within a molder’s network. It’s a perfectly acceptable practice, but not always the most efficient. That’s why Kaysun developed a range of vertically integrated in-house value-added services — to save our customers time and money without compromising part quality or introducing unnecessary risk.

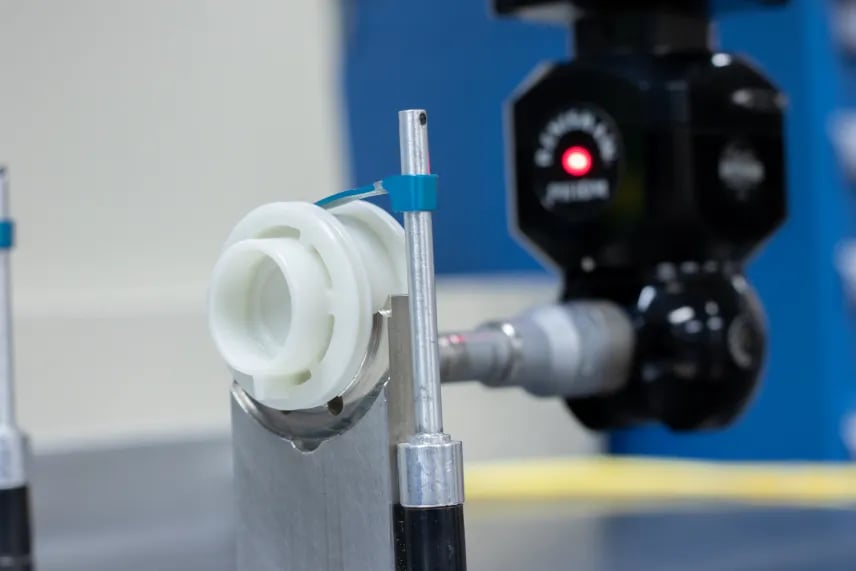

Quality Systems

There’s no substitute for injection molding quality. It’s the measure of an injection molder’s commitment to their craft and customers, and an OEM’s benchmark in their market and for their reputation. Kaysun manages every aspect of quality from the production floor, utilizing a skilled team and cutting-edge technologies and tools to ensure precision production and flawless solutions.

Does your company fit our ideal customer profile?

Complete the form to request a free consultation with our plastic engineering experts.