Injection Molding Resources

Kaysun Blog

Stay up-to-date on all things injection molding with the Kaysun Blog

Injection Molding Quotes: 5 Tips to Help Get Tooling Right

Few things impact injection-molded part quality as much as tooling desig…

READ MORE

4 Ways Reshoring Remains A Win for American Manufacturing

International trade tensions have brought heightened awareness to reshor…

READ MORE

Top 3 Custom Injection Molding Trends to Watch in 2025

Despite being considered more energy efficient and producing less waste …

READ MORE

How Kaysun’s Culture of Sustainability Benefits OEMs and The Planet

Injection-molded parts and products are staples for OEMs in industries r…

READ MORE

The Impact of Non-Uniform Injection Molding Wall Thickness

Shrink rates for plastic parts vary depending on the materials used and …

READ MORE

12 Common Injection Molding Questions — Answered!

Injection molding is a versatile and precise process, making it ideal fo…

READ MORE

How Centralized Material Handling Streamlines Injection Molding

We consistently look for new ways to deliver timely service and top-qual…

READ MORE

How RJG Master Molder I/II Defines Injection Molding Excellence

In custom injection molding, quality and precision are both an expectati…

READ MORE

5 Engineering Factors That Improve Your Injection Molding Project

In many complex industries, decisions about which injection molder to us…

READ MORE

Why Continuing Plastic Engineering Education Matters to OEMs

Technologies, product needs, and customer expectations are rapidly advan…

READ MORE

Guides & Whitepapers

Case Studies & Part Histories

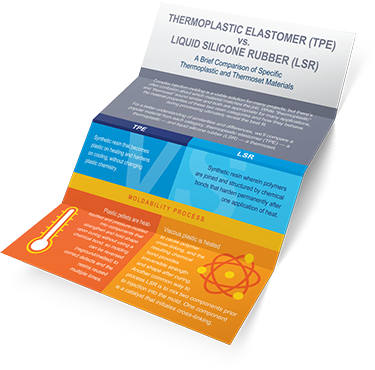

Tip Sheets, Infographics & Checklists

Videos

Central Material Handling System Overview

Engineering Capabilities and Bandwidth

Quality Lab Overview

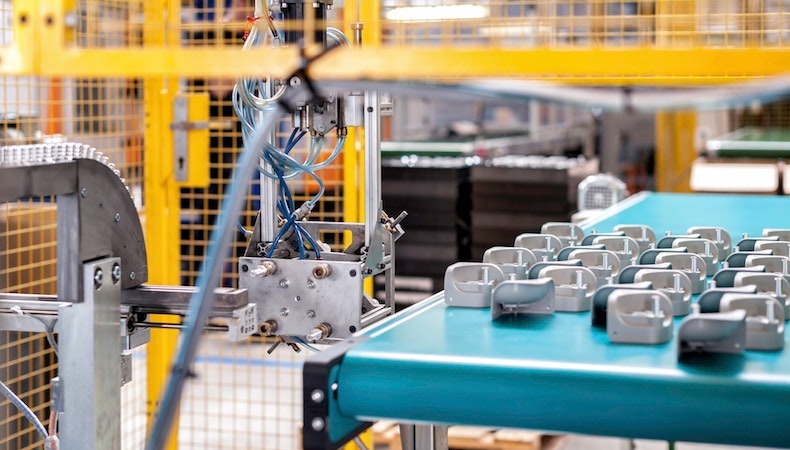

The Benefits of In-House Automation Capabilities for Injection Molding Projects

Kaysun's Process Development Methodology: Scientific Molding

How Kaysun Approaches Design for Manufacturability (DfM) Part 1: Moldflow Analysis

How Kaysun Approaches Design for Manufacturability (DfM) Part 2: Part Analysis

How In-House Tooling Streamlines Projects and Meets Customer Needs

Scientific Molding in Action