The Kaysun Quality Lab brings quality assurance in-house

Quality control is integral to injection molding. Without a quality benchmark, accuracy and precision become moving targets. Parts are subject to inconsistencies, defects, or failure. Injection molding processes lack repeatability and adaptability. You could be facing a high-dollar spend with little — if anything — to show for it.

What Sets Kaysun Apart

A lot is riding on the quality of your injection molded parts. It’s a smart business decision to partner with a custom injection molder that is passionate about quality control and prepared to hold your projects — and themselves — to uncompromising standards.

Our in-house Quality Lab serves as a hub for cross-functional collaboration, comprehensive testing, and unparalleled injection molded part and process quality management.

Key Quality Processes

Kaysun is a trusted partner to manufacturers in many industries. Our broad experience gives us the unique ability to apply learnings from one market to a similar situation in another, often resulting in fresh perspectives and powerful innovation.

Automotive and medical manufacturers typically require variations on the same quality themes, as dictated by their respective industries.

As such, Kaysun Quality Engineers are knowledgeable about and continue to expand in quality-related areas that serve both, following the quality process principles of:

- Advanced Product Quality Planning (Automotive)

- Product Validation (Medical)

Certifications

Kaysun is deeply committed to quality. The knowledge and integrity behind the certifications we hold reflect that commitment and assure our customers that every injection molded part and process we engage with meets or exceeds rigorous industry standards.

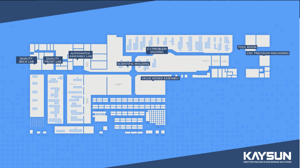

Cutting-Edge Equipment and Technologies

Quality control checks for injection molding require cutting-edge testing equipment, like that found in our in-house quality lab:

- Moisture content testing: Water absorption negatively impacts the performance characteristics of many resins. Structural defects that are not plainly visible or easily identifiable, voids, or air pockets could also put parts at risk. Applying the Karl Fisher Titration method gives Kaysun accurate results and timely insights that could prevent costly rework or failures. The Karl Fisher Titration method chemically reacts with water while ignoring other volatiles to accurately identify and calculate the moisture content percentage, which could be inflated when using a weight loss method of inspection.

- Structural (destructuve) and fatigue testing: Instron is a world leader in destructive testing methodologies. Stress testing and cyclical testing to failure in-house allows Kaysun engineers to qualify specifications or adjust materials to course correct prior to or during production. Further, by pulling representative sample parts from production lines for intermittent testing of weld strength, impact strength, and other specific testing gives Kaysun engineers insight into how and why materials fatigue impact parts. Injection molded parts are deemed high quality once they pass comprehensive testing.

- CMM inspection: Using coordinate measuring machines provides precision in injection molded part geometries. CMM testing allows Kaysun engineers to verify the accuracy of parts produced against the intended design specifications.

- CT inspection: Computer tomography is a nondestructive technique for visualizing the interiors of injection molded parts. This “inside out” analysis provides opportunities for identifying non-visible defects that could promise part quality.

Kaysun quality engineers working independently or in cross-departmental collaborations can verify process stability and product viability while in production. The ability to test proactively during development phases or reactively in response to production errors is a capability that few molders can offer.

Quality is the touchstone that brings all facets of an injection molding project together. In-house capabilities give Kaysun the expertise and flexibility to facilitate quality assurance throughout — from the supply side and customer outreach to internal collaboration on design, engineering, testing, and production.

It’s a rare and well-rounded approach that you can only find in a true custom injection molding partner, like Kaysun.