How VA/VE Improves Injection Molding Quality Control

Value Analysis/Value Engineering (VA/VE) is a systematic approach to cost management. Using value engineering (VE) during the design phase of a new injection-molded part balances part cost and functionality — especially when an experienced molder is engaged early on to implement VE. In short, the process ensures a part’s value is improved at each stage of its life cycle.

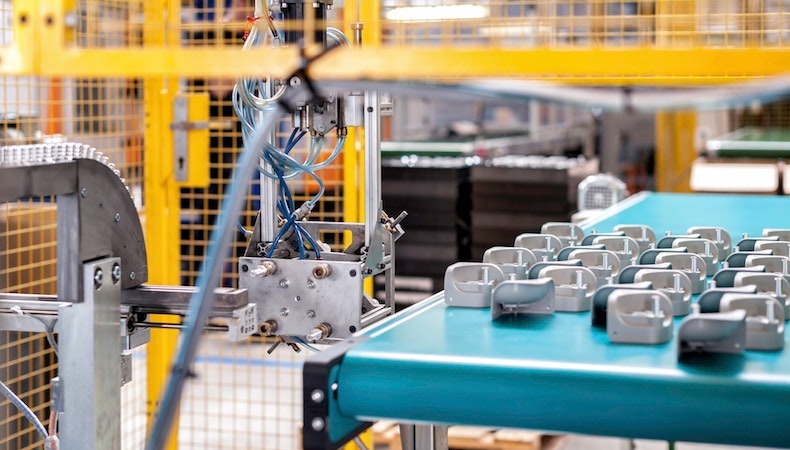

Value analysis (VA) is similar to VE in that it focuses on cost reduction. However, instead of being applied during design of a new part, VA is used during production of existing parts. Each stage of production and every line item cost is evaluated to determine how it contributes to an existing part’s value and if it’s doing so at the lowest possible cost without jeopardizing functionality.

If VA determines an element of existing part production is unnecessary or not cost-optimized, elimination or adjustment may take place which drives down costs.

The budgetary advantages of VA/VE are evident, especially when manufacturers choose to work with an experienced injection molder. What VA/VE also provides are opportunities for injection molders to monitor and manage part quality.

Cost Effectiveness and Part Quality

The search for cost effectiveness assesses design, engineering, materials, processes, tools, etc. — essentially everything that also impacts quality. Representative questions that may be posed include:

- Are there alternative materials available?

- How is waste and scrap managed?

- Does the part design incorporate tight tolerances and other features that may interfere with production?

- Is tooling appropriate for the tolerances and other requirements of the application?

- What do the injection molding process parameters look like in terms of temperature, pressure, speed, and cycle time?

Answers speak to both cost reduction and quality control when an injection molder is qualified to use Design for Manufacturability (DfM) and Failure Mode and Effects Analysis (FMEA), among other highly specialized and technical tools.

However, not all risk to part quality lies squarely in the processes.

Supply Chains, Sourcing, and the Effects of Global Events

The global pandemic was instructive for manufacturers about many things. Of particular impact was the repercussions of worldwide supply chain disruption. On the heels of the pandemic there was substantial unrest between certain countries, which also contributed to the chaos manufacturers were already trying to manage.

While the plastics industry has navigated through much of the aftermath, it’s left a lasting impression. There is heightened sensitivity around escalating tensions among nations, especially significant players in the plastics and injection molding markets such as China.

Many OEMs are making choices to reshore, source materials elsewhere, and re-establish operations in other countries prior to any potential conflict. Strategic decisions now may mitigate consequences later. It also could give OEMs the chance to partner with a U.S.-based injection molder that can help manage suppliers and sources, all while improving part quality and outcomes.

Continuous Improvement: Best Practices, Better Results

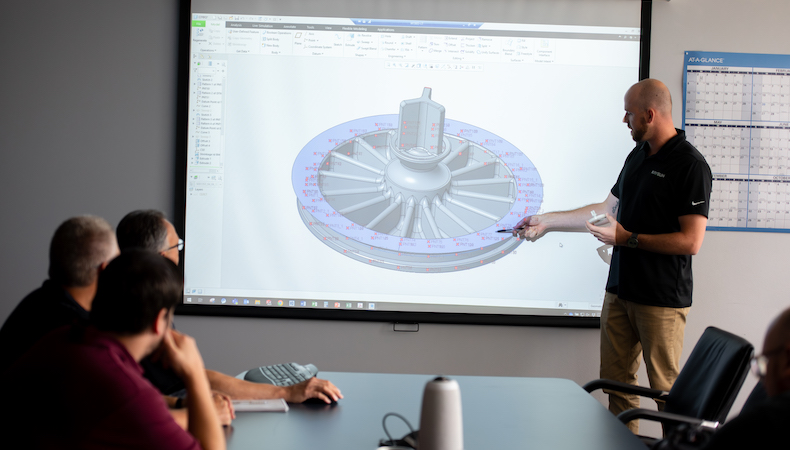

Kaysun is well-versed in VA/VE, which is central to our approach to every injection molding program. In fact, to consistently deliver on our promises to our customers, we are deeply committed to continuous improvement.

A testament to that commitment and to best practices is our Quality Lab. It allows Kaysun teams to engage with each other, cutting-edge technologies, and testing equipment to ensure quality is top of mind throughout all project phases. Verifying process stability and product viability at regular intervals reinforces quality outcomes.

Like cost management, there is no one-and-done approach to quality control. It takes an injection molder with the expertise and dedication to continuously improve and implement practices that focus on controlling time, expenses, and quality.

The Injection-Molded Part Quality Control Checklist is a great tool for understanding how to leverage your injection molding partnership to your best advantage. Click below to download your copy.

Subscribe

TO OUR BLOG

How Do Injection Molder Partnerships Influence Project Costs?

You Might Also Like...

The Impact of Non-Uniform Injection Molding Wall Thickness

Shrink rates for plastic parts vary depending on the materials used and the unifor…

READ MORE

5 Engineering Factors That Improve Your Injection Molding Project

In many complex industries, decisions about which injection molder to use for cust…

READ MORE

Why Continuing Plastic Engineering Education Matters to OEMs

Technologies, product needs, and customer expectations are rapidly advancing. OEMs…

READ MORE