Industrial Metal-to-Plastic Conversion: 3 Case Studies

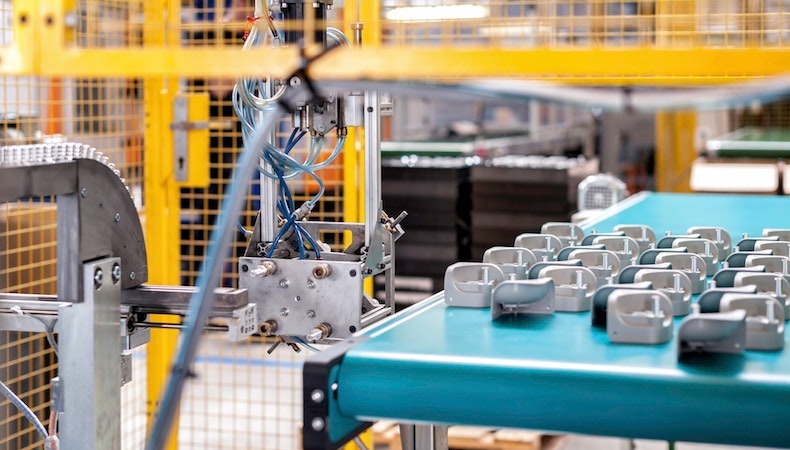

Several industrial sectors are converting metal components to plastic to gain efficiencies in cost, weight, performance, aesthetics, and durability. While these are compelling reasons to consider plastic versus metal, the process isn’t necessarily right for all industrial applications.

A comprehensive feasibility analysis can help you determine if your project is suitable for metal-to-plastic conversion by evaluating it from three fundamental perspectives: design, manufacturability, and return on investment.

DESIGN

To assess whether your metal component’s design is effective for conversion to plastic, or if it’s possible to modify a metal part to accommodate conversion, it is critical to understand how the product will be used. Design engineers must accurately evaluate the product’s real-world environment, including temperature, mechanical impact/load, electromagnetic/radio frequency interference (EMI/RFI), etc., to ensure the product won’t succumb to premature field failure.

To arrive at the best material choice and ultimately to decide whether your project is a fit for converting from metal to plastic, it’s important to examine these elements holistically. Making assumptions could potentially derail the entire development process.

Case Study #1

This was the case for a leading food waste disposer manufacturer in need of a complex housing component that could withstand the extreme conditions of the machine in operation. After a thorough analysis, Kaysun engineers guided plastics selection that balanced the required strength with moldability compatible with the machine’s seals and other plastic, metal, and rubber components.

MANUFACTURABILITY

Function is one aspect of design evaluation, but it’s a moot point if the component can’t be manufactured. Design for Manufacturability (DfM) focuses on proactively designing products to optimize fabrication, assembly, and testing. These characteristics are largely dictated by the materials from which components are constructed.

Traditionally, metal is the default choice when strength and durability are in demand. But with proper material selection and design optimization, plastics can reduce weight and deliver the strength of metal. Still, that doesn’t guarantee manufacturability. A custom injection molder that’s experienced in complex applications is your best bet to answer the question. Their expertise in plastics behaviors and scientific molding can guide your decision process.

Case Study #2

A company in the mining industry approached Kaysun about manufacturing an air-operated double diaphragm pump in plastic instead of metal. The goal was to cost-effectively extend pump life by increasing resistance to corrosion and chemicals. The Kaysun team worked collaboratively with the OEM’s engineers to select plastics with mechanical and chemical properties congruent with the pump’s environmental conditions.

The process also required a part design adjustment to better fit the injection molding process. Structural ribs and material core-outs were added to minimize thick sections and balance material flow. The final product met all the performance goals — including lower production costs. The complex injection-molded part continues to be manufactured today.

COST/RETURN ON INVESTMENT (ROI)

Even if your project is manufacturable in plastic, cost largely determines if metal-to-plastic conversion makes sense.

Often, industrial OEMs look to reduce shipping and production costs by making a component out of plastic instead of metal. But in some highly technical or complex applications, the cost of required plastics and/or production processes to achieve end-use performance may negate other potential cost savings. To prevent expensive surprises, it’s critical to conduct a cost analysis to verify the total return on investment (ROI) before moving forward with production.

Case Study #3

When a lighting company transitioned to light-emitting diode (LED) lamps within a certain metal fixture, there was a corresponding drop in required temperatures that the fixture needed to withstand. As such, the application was a perfect candidate for metal-to-plastic conversion. Kaysun helped the company through the process and arrived at a quality, cost-effective solution that uses plastic instead of metal near the light source.

Metal-to-plastic conversion is often ideal for industrial applications, but the decision warrants careful feasibility analysis of design, manufacturability, and total ROI. The best way to achieve a meaningful analysis is to collaborate with an experienced custom injection molder, just as the Gates Corporation did when they reached out to Kaysun to determine feasibility, identify cost-saving opportunities, adjust design. Get the details in our case study, Metal-to-Plastic Conversion Cuts Costs, Maintains Performance Standards for Belt Tensioning Pulley Assembly. Click the button below to access your copy now.

Subscribe

TO OUR BLOG

How Do Injection Molder Partnerships Influence Project Costs?

You Might Also Like...

The Impact of Non-Uniform Injection Molding Wall Thickness

Shrink rates for plastic parts vary depending on the materials used and the unifor…

READ MORE

5 Engineering Factors That Improve Your Injection Molding Project

In many complex industries, decisions about which injection molder to use for cust…

READ MORE

Why Continuing Plastic Engineering Education Matters to OEMs

Technologies, product needs, and customer expectations are rapidly advancing. OEMs…

READ MORE