How Automation and Robotics Augment Injection Molding

As Industry 4.0 continues to evolve, the Internet of Things (IoT) takes on even greater importance. Automation and robots for injection molding machines are routinely found — and expected — on production lines as OEMs and custom injection molders lean into the future.

Intelligent Use of Smart Technology

Data and analytics rule the day, and the current trends1 reflect it. Smart technology is instrumental in several facets of production, as they:

- Streamline certain functionalities by introducing interfaces and capabilities that allow individual operators to perform several key tasks simultaneously, saving time and money

- Collect and analyze data from multiple sources, applying results in near real-time so maintenance and downtime are minimized. OEMs are assured of efficient production

- Allow for automated job setup with electronic parameter setting and recall for operations including molding and drying

- Monitor production for errors and proactively transmit alert data as to corrections and overall process optimization

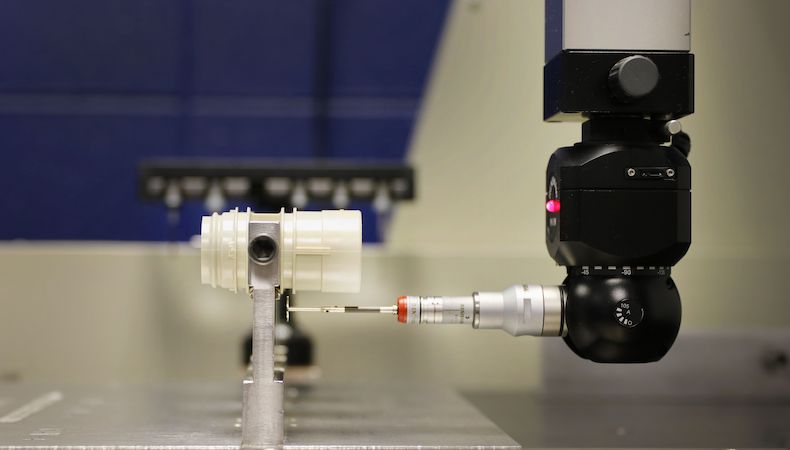

Robotics Lend a Hand

The efficiencies gained through the advent of Industry 4.0 and smart technologies is further enhanced by robots for injection molding machines. Having these versatile tools available in work cells aids in speeding up repetitive tasks like loading and unloading components from equipment.

Time and cost efficiencies increase exponentially as robotics are used in key processes2, including:

- Insert loading

- Overmolding-related functions such as part placement, trimming, and de-gating

- Sonic and laser welding

- Decoration and labeling

- Pre-treatment of plastic parts for application of adhesives or paint

Current and emerging trends suggest that custom injection molding continues to advance, benefitting OEMs in all project phases, from design through production and go-to-market strategies.

An experienced custom injection molder with the foresight to see what’s on the automation horizon and incorporate it into their processes is the partner you want – and need – for leveraging Industry 4.0. Learn more by watching our short video, Injection Molding Automation in Action.

SOURCES

1Travelers, 5 Internet of Things (IoT) Trends in Plastics Manufacturing, Undated

2Robots.com, The Robotic Future in Injection Molding, Undated

Subscribe

TO OUR BLOG

How Do Injection Molder Partnerships Influence Project Costs?

You Might Also Like...

Top 3 Custom Injection Molding Trends to Watch in 2025

Despite being considered more energy efficient and producing less waste than other…

READ MORE

How Cutting-Edge Quality Control Checks and Tech Elevate Injection Molding Projects

In theory and practice, industrial automation has been part of the U.S. manufactur…

READ MORE

How In-House Injection Molding Automation Benefits OEMs [VIDEO]

In the United States, about 70% of robotics technologies are used within four indu…

READ MORE

![Injection Molding Automation In Action [video]](https://no-cache.hubspot.com/cta/default/22287/1ed622c2-01d6-4255-8689-1e654ced06e4.png)