Overmolding

According to global aging data compiled by the United Nations, by 2050 1 in 6 people in the world will be over the age of 65.1 That's a dramatic jump from current statistics that place the same segment of the population at 1 in 11.1

As a result — and in light of spikes in medical demand due to COVID-19 for all age groups — healthcare is rapidly shifting from clinics and hospitals to in-home care and smaller, non-traditional facilities.

Portable medical devices that monitor diagnostic and therapeutic data and aid in treatment of certain conditions are integral to this transition. Use of wearable technologies alone have increased by 26% globally2, and the U.S. medical device market has seen a 1.9% uptick in 2020 to $45.3 billion3.

The global need is evident, and the universal solution is found in injection-molded medical devices.

Plastic is lightweight and can conform to nearly any shape, which is beneficial to medical applications wherein portability and ease of use by inexperienced users or traveling healthcare workers is necessary. Portable medical devices also need to be durable and perform reliably. That’s where custom injection molders that are experienced in overmolding make key contributions.

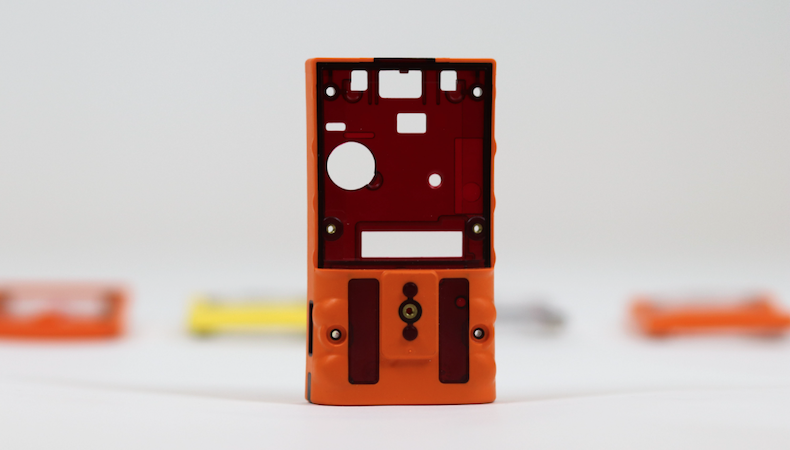

Overmolding is a unique injection molding process that combines two or more molded plastic parts into one finished product to add or enhance certain characteristics.

For medical applications that may mean covering a rigid device “skeleton” with a soft, flexible outer shell to:

In addition to these product outcomes, brand and business advantages can be realized by partnering with an experienced custom injection molder for overmolding projects, including:

Overmolded components provide attributes that build performance capabilities in a wide range of medical applications, including:

Empowering individuals and healthcare workers to administer in-home services requires medical devices that reliably perform, regardless of location or user familiarity. Overmolded medical components and portable medical devices solve today’s challenges with an eye to future healthcare industry needs.

For more on how custom injection molders use overmolding to help solve some of the toughest medical application challenges, download our eBook, Overmolding for Medical Device Manufacturing.

SOURCES:

1United Nations, World Population Aging 2019: Highlights, 2019

2Medical Product Outsourcing, Top 10 Trends in the Medical Device and Equipment Industry, September 18, 2019

3IBISWorld, Medical Device Manufacturing in the US Market Size 2005-2026, Undated

Injection-molded parts are integral to the performance and aesthetics of a wide ra…

READ MORE

Popular across many industries, overmolding may initially appear to simply enhance…

READ MORE

Increasingly popular with manufacturers of consumer products, medical devices, and…

READ MORE