Medical Injection Molding

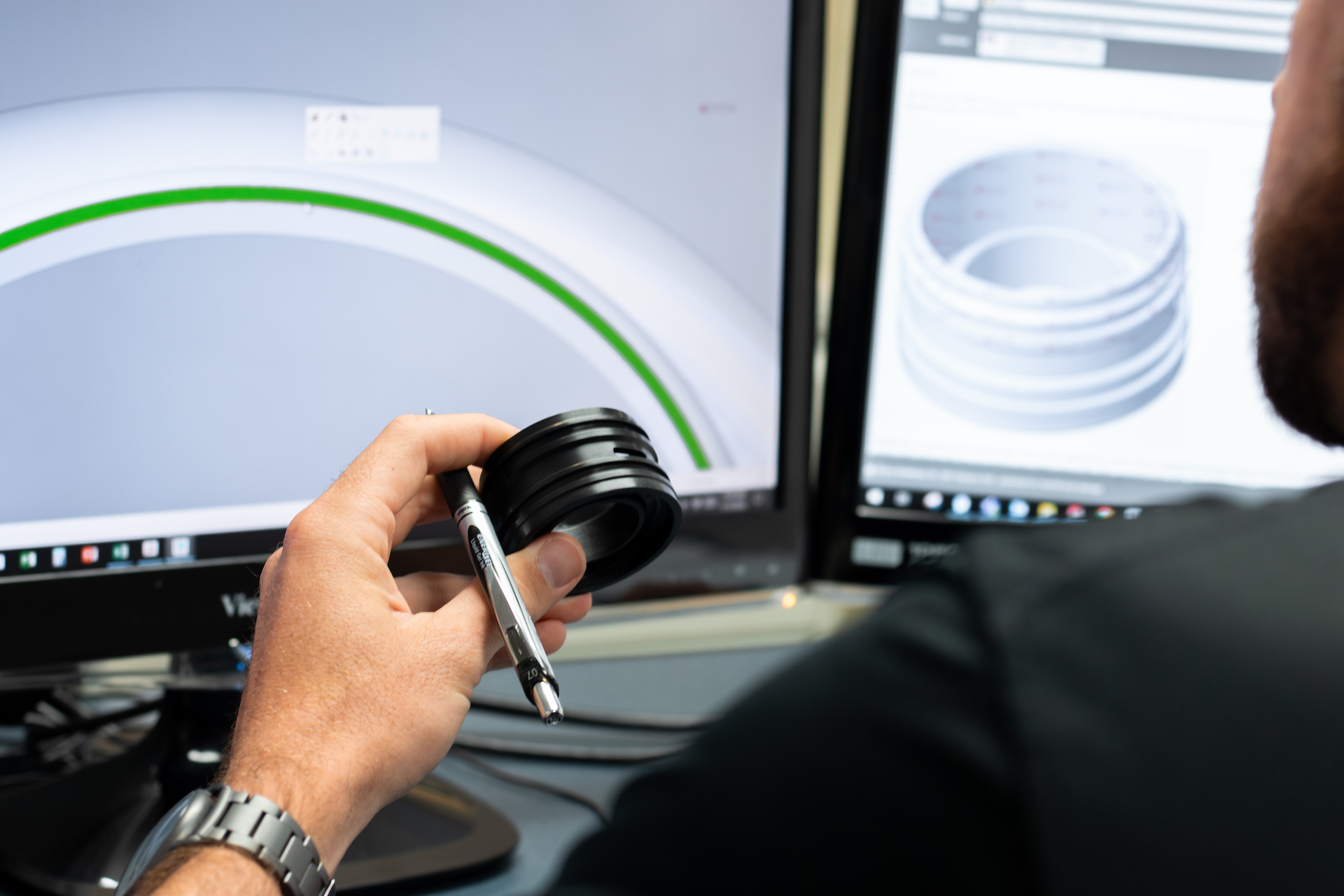

As medical device design evolves to provide ever-improving healthcare outcomes, manufacturers are partnering with full-service, experienced custom injection molders to gain increased design freedom and process efficiencies.

Partnering with Kaysun — one of the few injection molders in the country to hold MedAccred Plastics accreditation — is a consistent value-add from part and tooling design through material selection and process control. It empowers many medical OEMs to address issues before they impact production or the bottom line.

Kaysun Carries

MedAccred Plastics

Accreditation

MedAccred is a Performance Review Institute medical device industry-managed supply chain oversight program dedicated to reducing patient safety risk. It focuses on critical manufacturing processes compliance and device quality and consistency.

Earning accreditation is a rigorous process, and only a small fraction of medical injection molding companies receive the distinction.

Kaysun has carried the MedAccred Plastics accreditation since 2020, demonstrating our ongoing commitment to excellence and assuring medical OEMs of an unparalleled benchmark of production and quality standards.

Why MedAccred Accreditation Matters to Manufacturers

Leverage Injection

Molder Design

Expertise to Gain

Competitive Advantage

The rapid advancement of the medical industry necessitates constant innovation and complexity in medical device design. Smaller sizes, more intricate geometries, progressive functionalities, and portability are among the greatest needs in today’s medical equipment — and among the biggest challenges for design and engineering teams.

Leveraging the experience and knowledge of medical injection molders during the design phase of complex applications can help overcome the unique challenges of medical injection molding and improve outcomes.

THESE RESOURCES DEMONSTRATE HOW:

Improve Performance

& Satisfaction with

Medical Overmolding

Portable medical devices are a mainstay in hospitals, emergency vehicles, and outpatient environments. The devices must remain accurate and functional; however, drops, bumps, and excessive vibration are inevitable as equipment is transported from place to place.

Overmolding is a proven solution for shock and vibration reduction, sound dampening, electrical insulation, improved chemical/UV resistance, effective oxygen and moisture barrier protection, and color infusion.

THESE RESOURCES EXPLAIN THE SPECIALIZED EQUIPMENT, EXPERIENCE, AND TRAINING NECESSARY FOR MOLDERS TO CAPABLY OFFER OVERMOLDING SERVICES:

The Importance of Involving Injection Molders in Materials Selection

Medical device performance is largely dependent on the characteristics of the materials used and application needs such as strength, flexibility, transparency, biocompatibility, safety-enhancing microbe resistance, and temperature and chemical resistance. With thousands of engineered materials to choose from, it's important to work with experts in medical device injection molding.

THESE RESOURCES DEMONSTRATE HOW:

The Perfect Partner,

The Perfect Part

Medical OEMs are tasked with providing consistent, high-performance solutions to the challenges posed by a variety of complex applications. Partnering with a custom injection molder that has the experience, knowledge, technical expertise, and certifications needed to adhere to the exacting standards of the medical industry is imperative.

Not every molder is qualified, but those who are — like Kaysun — can move your business forward with confidence.

AS REFLECTED IN THESE RESOURCES:

Medical Injection Molding Experts

Kaysun is experienced with medical product design, production, and assembly. We are ISO 13485:2016 certified and MedAccred Plastics accredited.

WHAT OUR MEDICAL CUSTOMERS SAY

“Kaysun exceeded our expectations in all areas. They made a complex, gigantic program easy from an engineering standpoint. Working with the Kaysun engineering team is like a hot knife through butter.”

DAVE D.

Senior Industrial Designer

Kaysun Blog

How MD&M West 2024 Keeps MedTech Professionals Ahead of the Curve

MD&M West is one of the largest and most respected medical device trade shows …

READ MORE

How MedAccred Accreditation Helped Kaysun Enhance Processes & Quality Systems

When you operate at the top of your game, reach higher. Kaysun had already shown i…

READ MORE

Why Ongoing MedAccred Accreditation Matters to Medical Manufacturers

Kaysun's commitment to excellence is well documented through its certifications, i…

READ MORE

Does your company fit our ideal customer profile?

Complete the form to request a free consultation with our plastic engineering experts.