8 Cutting-Edge Medical Device Advancements

Advancements in the medical industry are happening rapidly. Injection-molded medical devices coming to market address a wider range of patient issues and, in some cases, are designed to work autonomously to assist staff in treatment — functionalities that demand precision performance.

Broader Applications

A wide range of patient applications is being explored for use with complex injection-molded medical devices:

- Wearable sensors. Wearable health sensors could soon change the way people control and monitor chronic diseases like diabetes, heart disease and asthma. Devices — from stick-on sensors to wristbands and special clothing — are already being used to monitor respiratory and heart rates, including EKG readings, temperature and glucose levels. Drug companies and researchers are looking into using wearable technology to monitor patients more accurately in clinical trials, and hospitals and outpatient clinics could use it to monitor patients after discharge.

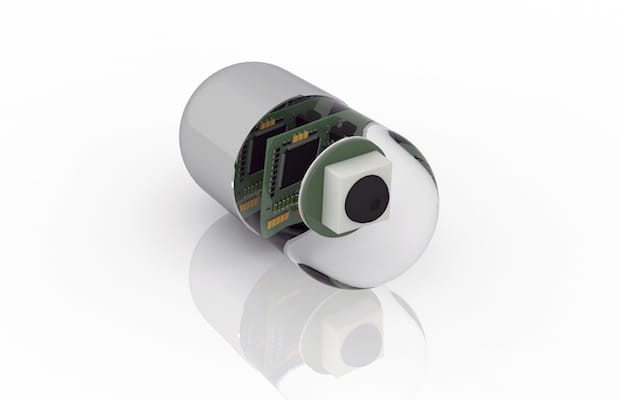

- Pill-sized cameras. Breakthrough medical devices like swallowable cameras could soon replace invasive diagnostic medical procedures like colonoscopies. Similarly, these “video pills” are the focus of researchers from the University of Glasgow School of Engineering who are exploring their use as alternatives to intrusive endoscope imaging, and as clinical tools to detect the presence of throat and gut cancers.

- Robots. The use of robots in medical settings is expanding beyond the emergency room and robot-assisted surgery to patient care and comfort. In France, a newly introduced injection-molded interactive robot helps children during anxiety-provoking medical procedures, particularly vaccinations. The robot is designed to engage children through conversation and toys, drawing attention away from the procedure and keeping them calmer.

Current Technologies

Over the past few years, several companies have expanded their product lines to manufacture and market medical devices that incorporate forward-thinking technologies:

- Airora™ devices by Tri-Air Developments, Ltd. continually clear indoor air of viruses and bacteria. Airoa™ devices are available in commercial and consumer models. Commercial products target malodor within washrooms and kitchens; and are being developed to tackle issues found in professional healthcare and food manufacturing. Consumer products will address indoor allergens, malodor and various indoor pollutants like VOCs, formaldehyde and carbon.

- The Dechoker anti-choking device, developed and introduced to the market by Dechoker, LLC, is an alternative to the Heimlich Maneuver or tracheotomies to clear airway obstructions. The plastic Dechoker is comprised of a mask that seals over the victim’s nose and mouth, a tube that depresses the tongue and partially inserts into the throat, and a syringe-like plunger that uses air pressure to remove the obstruction when pumped. The patent-pending Dechoker device is FDA-approved for all three sizes: adult, child and toddler.

- The Portable Neuromodulation Stimulator (PoNS) 4.0 device, manufactured by Ximedica® and currently being used in Helius Medical Technologies’ clinical trials, treats a balance disorder caused by traumatic brain injury. The PoNS 4.0 is a non-invasive injection-molded plastic device that is placed around the patient’s neck and into the mouth, and delivers neurostimulation to the brain through the tongue’s nerve fibers and ancillary connections to the brainstem and cranial nerves.

- The Vios Monitoring System from Vios Medical connects patient-worn sensors with a bedside monitor and central station monitor software to automatically and continuously analyze, display and centralize patient data in near real time. To minimize irritation on patients’ skin but not compromise durability, several components of these devices are injection molded from Bayblend polycarbonate/acrylonitrile butadiene styrene (PC+ABS) and Texin thermoplastic polyurethane (TPU) supplied by Covestro.

- Haemoband PLUS, an improved version of the original Haemoband, both offered by Haemoband Surgical, is used in the rubber band litigation (RBL) clinical treatment of hemorrhoids. Denroy Plastics, Ltd., manufactures the injection-molded plastic device and individually molded latex-free bands in its recently installed the room facility.

The evolving medical landscape includes devices that rely on injection molded plastic components for precision and performance. Partnering with an experienced injection molder is essential, especially one holding MedAccred Plastics accreditation and a team of engineers with deep knowledge of scientific molding. Learn more in our whitepaper, The Importance of Scientific Molding in Medical Device Manufacturing. Click the button below to access your copy now!

Subscribe

TO OUR BLOG

How Do Injection Molder Partnerships Influence Project Costs?

You Might Also Like...

How MD&M West 2024 Keeps MedTech Professionals Ahead of the Curve

MD&M West is one of the largest and most respected medical device trade shows …

READ MORE

How MedAccred Accreditation Helped Kaysun Enhance Processes & Quality Systems

When you operate at the top of your game, reach higher. Kaysun had already shown i…

READ MORE

Why Ongoing MedAccred Accreditation Matters to Medical Manufacturers

Kaysun's commitment to excellence is well documented through its certifications, i…

READ MORE