Automation

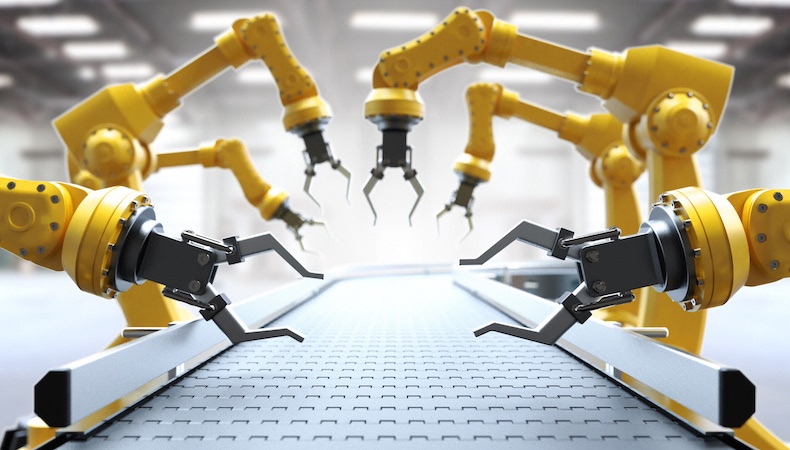

Among plastic injection molders, there can often be a tradeoff between their ability to custom manufacture parts on an individual basis and their capability to automate the production process for high-volume cost-efficiency. The reality is that, with the proper injection molding partner, automation and its associated benefits can be within the grasp of companies even if they have smaller production runs. Here are three ways that injection molding automation can help level the playing field among manufacturers:

Quality does have a cost, but the cost of poor quality can be even greater over the life cycle of a product. This is why your number-one manufacturing consideration should be consistent product quality. That is, the manufacturing process turns out the same product every time, minimizing or even eliminating the risk of human error. Should something go wrong, the proper automation process is accountable enough to trace it to its point of origin, where corrections can then be made with little down time.

The ability of a manufacturer to efficiently and effectively automate the production process is key to allowing an OEM to turn out a product at a competitive price point. Production by automation also helps retain quality assurance and keep work in the United States.

Kaysun has a full array of adaptable automated equipment and the in-house expertise to configure the production process to each manufacturer's individual needs. Having all these resources in one place allows us to control costs for low volumes, as well as optimize it for high volumes. This allows a small manufacturer to be at the same or similar level as a large player, regardless of their production run size.

The sooner you engage us as a partner for an automated manufacturing processes, the easier it will be to achieve the optimal solution. Interested in learning more about gaining a competitive advantage in the injection molding process? Download our Complex Injection Molding for a Competitive Advantage whitepaper.

Industry 4.0 has made manufacturing more dynamic than ever before. Merging IoT, AI…

READ MORE

Despite being considered more energy efficient and producing less waste than other…

READ MORE

In theory and practice, industrial automation has been part of the U.S. manufactur…

READ MORE